Tag Archives: equipment

When the manager of a seafood processing plant is evaluating different options for a seafood processing equipment, yield is an important criteria.

Yield performance occurs in different ways around the processing activity.

Usually the processing equipment manufacturer will focus on the yield provided by their own equipment and will provide data only related to the equipment. In a fully automated system, a 100% performance is rarely achievable with an average fish or seafood catch. The processor should expect that a certain percentage of the product fed in the fully automated fish processing system will not be processed perfectly. If an equipment manufacturer states that their machine provides a 100% yield, the purchaser should be suspicious and should start asking questions.

In a semi-automated system, a 100% efficiency is easier to achieve. The worker can complete a self-evaluation and can "rework" the product until the processing is fully completed according to requirements.

The plant manager should investigate the following aspects of the process that will have an impact on the productivity.

1. Pre-process

This refers to the requirements of the seafood product that can be fed in the machine. They are usually provided by the equipment fabricator. These requirements allow the achievement of the optimal yield. These requirements might regard size, weight, the level of cleanliness, or other specifications. This means that, for example, a sorting system, a cleaning line or an inspection station are required and must be installed before the processing machine, so that only the products meeting the required parameters are fed in the equipment. The product that is not compatible with the equipment specifications, but that still needs to be processed, may need to be calculated in the overall productivity.

2. Parallel process

The production plant manager should then plan how the fish or seafood product that is incompatible with the equipment should be managed. Depending on the machine requirements, the manager might, for instance, evaluate the possibility of:

- Processing the fish by hand.

- Complete the required change to the seafood product so it can be fed in the processing system.

- Processing the raw fish or seafood into another finished product.

The costs of performing these additional processing steps should be calculated in the overall processing cost and efficiency.

3. Tracking rejects

The processor should also investigate what happens to the fish or seafood product that went through the processing equipment but is not processed according to the expected requirements. This is what is usually announced by the equipment manufacturer. Usually the processing equipment manufacturer should provide solutions on how to manage these so called “rejects”. Are the products automatically sorted and placed apart? Do they remain mixed with the good product? If the rejected product is sorted, can it still be recuperated, for instance processed manually? Or does it have to be destroyed and be considered a complete loss? If the off specification product is mixed with the good one, should an inspection station be planned? Can this inspection be automated or does it have to be manual? If the off-grated product cannot be sorted out and must remain mixed with the good one, the plant manager should evaluate how this loss of quality affects the overall value of the production run.

When investing in a new processing equipment, calculating the entire process performance and yield is important because it provides the plant manager with an accurate picture of his return on investment.

PROCESSING AND MARKET

The main market for sea cucumbers is processed products. A limited amount of raw sea cucumber is eaten worldwide.

In Asian markets, wild sea cucumbers are preferred over those produced from aquaculture, and sea cucumbers harvested from cold and arctic waters have a higher value over those from tropical and warm waters.

PROCESSING AND MARKET

The main market for sea cucumbers is processed products. A limited amount of raw sea cucumber is eaten worldwide.

In Asian markets, wild sea cucumbers are preferred over those produced from aquaculture, and sea cucumbers harvested from cold and arctic waters have a higher value over those from tropical and warm waters.

The processing of sea cucumbers depends on the market demand for the final product. Sea cucumbers are rich in protein and are used in traditional Chinese medicine. They are also a highly sought after food item. The most common product produced from sea cucumber is dried body walls, which is a traditional part of Chinese cuisine. The process consists on eviscerating and gutting the cucumber, then cleaning and cooking it in boiling water, and then drying it.

The longitudinal muscles (referred as meat) are also extracted from the sea cucumber and prepared for niche markets.

The sea cucumber’s head alone, also called flower, can also be dried as a lower end product.

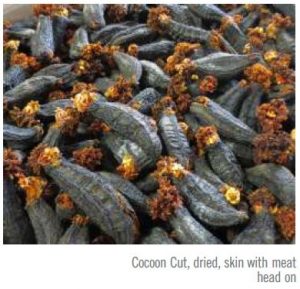

The quality and value of sea cucumbers depend on the thickness of the body wall, skin coloration and texture. Higher value products are composed of sea cucumbers presented in their undamaged, elongated and tube shape, also known as Cocoon Cut.

The most commonly processed sea cucumber products are:

- Cocoon cut, skin with meat, dry or frozen.

- Butterfly cut, skin with meat, dry or frozen.

- Butterfly cut, skin without meat, dry or frozen.

- Sliced skin, frozen.

- Raw meat, frozen.

COCOON CUT versus BUTTERFLY CUT: PROCESS DESCRIPTION

The following compares the two most popular sea cucumber processing methods, Cocoon Cut and Butterfly Cut.

Butterfly Cut

The butterfly cut process consists on first cutting the sea cucumber along its body to gain access to the internal organs. Once that cut has been produced, the sea cucumber is “unrolled” which gives it a butterfly like shape. To “unroll” the cucumber, it is required to entirely or partially cut the head off and to partially cut of the anus off . Cutting or not the head entirely off is determined by the end product needed to be prepared (with or without head on). Once the sea cucumber has been flatten out, the internal organs are manually removed (gutting), most often with a scraping tool. This particular processing method also allows the possibility to detach the meat from the skin, to prepare the frozen raw meat and skin without meat products. The meat is detached manually with a scraping tool. Once the sea cucumber has been gutted, it can go through the remaining processing stages, cleaning, cooking, drying and freezing, all depending on the required end product to be prepared. It must be noted that some equipment available on the market have automated the cutting and gutting stages of the butterfly cut process.

Cocoon Cut

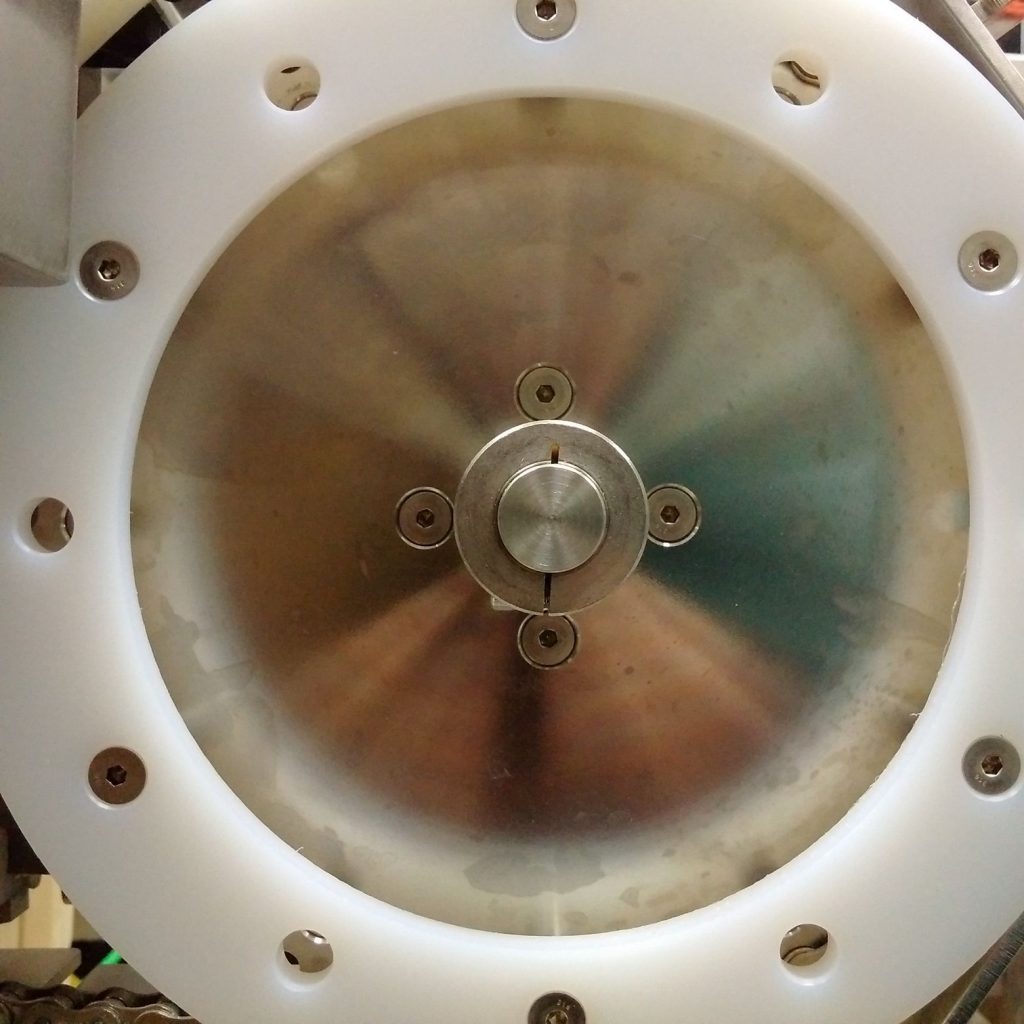

The cocoon cut is a much simpler process than the butterfly cut. It consist on cutting the head off to create an opening in which an especially designed cleaning tool is inserted to remove all the sea cucumber internal organs (gutting). The longitudinal cut - along the body - is not required. Cutting or not the head off is determined by the end product needed to be prepared (with or without head on). Once the sea cucumber has been gutted, it can go through the remaining processing stages, cleaning, cooking, drying and freezing, all depending on the required end product to be prepared. Oceatec’s cleaning line system is specially designed to produce the Cocoon Cut.

COCOON CUT versus BUTTERFLY CUT: COMPARATIVE ADVANTAGES

The processing of sea cucumbers depends on the market demand for the final product. Sea cucumbers are rich in protein and are used in traditional Chinese medicine. They are also a highly sought after food item. The most common product produced from sea cucumber is dried body walls, which is a traditional part of Chinese cuisine. The process consists on eviscerating and gutting the cucumber, then cleaning and cooking it in boiling water, and then drying it.

The longitudinal muscles (referred as meat) are also extracted from the sea cucumber and prepared for niche markets.

The sea cucumber’s head alone, also called flower, can also be dried as a lower end product.

The quality and value of sea cucumbers depend on the thickness of the body wall, skin coloration and texture. Higher value products are composed of sea cucumbers presented in their undamaged, elongated and tube shape, also known as Cocoon Cut.

The most commonly processed sea cucumber products are:

- Cocoon cut, skin with meat, dry or frozen.

- Butterfly cut, skin with meat, dry or frozen.

- Butterfly cut, skin without meat, dry or frozen.

- Sliced skin, frozen.

- Raw meat, frozen.

COCOON CUT versus BUTTERFLY CUT: PROCESS DESCRIPTION

The following compares the two most popular sea cucumber processing methods, Cocoon Cut and Butterfly Cut.

Butterfly Cut

The butterfly cut process consists on first cutting the sea cucumber along its body to gain access to the internal organs. Once that cut has been produced, the sea cucumber is “unrolled” which gives it a butterfly like shape. To “unroll” the cucumber, it is required to entirely or partially cut the head off and to partially cut of the anus off . Cutting or not the head entirely off is determined by the end product needed to be prepared (with or without head on). Once the sea cucumber has been flatten out, the internal organs are manually removed (gutting), most often with a scraping tool. This particular processing method also allows the possibility to detach the meat from the skin, to prepare the frozen raw meat and skin without meat products. The meat is detached manually with a scraping tool. Once the sea cucumber has been gutted, it can go through the remaining processing stages, cleaning, cooking, drying and freezing, all depending on the required end product to be prepared. It must be noted that some equipment available on the market have automated the cutting and gutting stages of the butterfly cut process.

Cocoon Cut

The cocoon cut is a much simpler process than the butterfly cut. It consist on cutting the head off to create an opening in which an especially designed cleaning tool is inserted to remove all the sea cucumber internal organs (gutting). The longitudinal cut - along the body - is not required. Cutting or not the head off is determined by the end product needed to be prepared (with or without head on). Once the sea cucumber has been gutted, it can go through the remaining processing stages, cleaning, cooking, drying and freezing, all depending on the required end product to be prepared. Oceatec’s cleaning line system is specially designed to produce the Cocoon Cut.

COCOON CUT versus BUTTERFLY CUT: COMPARATIVE ADVANTAGES

Advantages

Cocoon Cut

- Dry skin with meat product keeps its higher valued elongated and undamaged tubular shape. No longitudinal cut.

- Fewer processing steps for a cheaper processing cost and a faster process.

Butterfly Cut

- Possibility to produce the sea cucumber meat and skin without meat products.

Disadvantages

Cocoon Cut

- Entirely manual process is not possible, special cleaning tool is required.

- Detaching the meat from the skin is not possible while keeping intact the tubular shape.

Butterfly Cut

- The meat on skin product is damaged and does not retain the higher valued tubular shape.

- When fully manual, needs many required processing steps for a more expensive and elaborate process.

Advantages

Cocoon Cut

- Dry skin with meat product keeps its higher valued elongated and undamaged tubular shape. No longitudinal cut.

- Fewer processing steps for a cheaper processing cost and a faster process.

Butterfly Cut

- Possibility to produce the sea cucumber meat and skin without meat products.

Disadvantages

Cocoon Cut

- Entirely manual process is not possible, special cleaning tool is required.

- Detaching the meat from the skin is not possible while keeping intact the tubular shape.

Butterfly Cut

- The meat on skin product is damaged and does not retain the higher valued tubular shape.

- When fully manual, needs many required processing steps for a more expensive and elaborate process.

CONCLUSION

Due to the large variety of products that can be processed from the sea cucumber, setting up the right processing line can be confusing to processors. They simply must be aware and focus on the highest valued product that they can provide to their buyers on the long term.

They should also carefully analyse short term orders that might provide interesting commercial opportunities comparing to long term market trends that are pointing towards more added valued products, such as the Cocoon Cut sea cucumber.

This process selection also offers a tremendous opportunity to increase productivity and revenues while keeping the same number of workers and the same raw product supply. This is a strategic choice in these times of workers scarcity.

CONCLUSION

Due to the large variety of products that can be processed from the sea cucumber, setting up the right processing line can be confusing to processors. They simply must be aware and focus on the highest valued product that they can provide to their buyers on the long term.

They should also carefully analyse short term orders that might provide interesting commercial opportunities comparing to long term market trends that are pointing towards more added valued products, such as the Cocoon Cut sea cucumber.

This process selection also offers a tremendous opportunity to increase productivity and revenues while keeping the same number of workers and the same raw product supply. This is a strategic choice in these times of workers scarcity.

You can download this White Paper as a PDF file.

You can download this White Paper as a PDF file.