Author Archives: oceatec

Cube Automation (Tracadie, NB) announced earlier this week the acquisition of the assets of Oceatec (La Pocatière, QC), a company specializing in the design of automated equipment for the food processing and seafood industry.

«This acquisition will allow the our company to increase its presence in Quebec and offer its customers new technologies, said Roch Chiasson, president of Cube Automation. By adding this anchor in Quebec, we aim to better serve our customers and develop new market segments »

Founded 25 years ago, Cube Automation has been the leading provider of automation solutions for the seafood processing industry in Eastern Canada. Already having a strong presence in eastern Quebec, the company also offers its services to a variety of industry sectors, including those related to the integration of production lines, automation, robotics and the implementation of industry 4.0 solutions.

For 15 years, Oceatec has been working in the mechanical design of automated equipment, especially for the processing of seafood. Over the years, through the development of breakthrough innovations, the company has gained a dominant position in the processing sectors of sea urchins and sea cucumbers.

«By joining the Cube Automation team, we will have access to state-of-the-art automation and programming expertise," says Pierre Patenaude of Oceatec. For our clients in Quebec, Cube Automation's service offering will add value in the development of innovative solutions for the automation of industrial processes. »

In addition to its offices in Tracadie and Moncton, Cube Automation now has a business space in La Pocatière, Quebec, at Oceatec's facilities, which remain at the same address.

For more information:

Cube Automation

Dominique Gagnon, MBA

Sales Assistant / Marketing

506-393-6000 ext. 134

dominique.gagnon@cubeautomation.com

A Canadian company working in used cooking oil collection asked for our assistance for the development of a tank for its foodservice industry clients, mainly for the fast-food chains.

- New equipment design.

- Food residue collection for the production of an added value product.

- Positive environmental impact.

Focus on the Client's technical objective and market share gains

The goal was to develop a small capacity, small floor space, low cost tank, to store used oil and grease in restaurants for removal. The commercial objective was to deploy this new tank in a larger number of locations, to optimize pick-up logistics, to increase the amount of used food grade grease collected and to increase the company revenues in this market segment.

In this multidisciplinary project, our team proposed innovative solutions to meet the Client’s objectives.

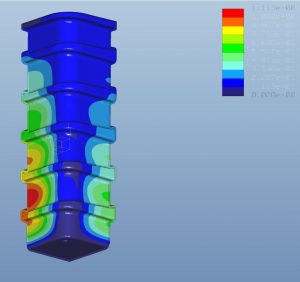

Our design team worked on the design of a plastic tank for its fabrication by the rotomolding process and completed the resistance calculations for the oil static load. A pumping system, adapted for this application, was also identified.

Illustration of the analysis to evaluate the tank resistance and deformation

Development of an innovative technology

We have included in the tank a system to read the oil level using an electronic remote sensor technology. This innovative solution doesn’t use traditional mechanical level measuring systems which are complex and unreliable in the presence of grease fume.

Also, to prevent oil stealing, we have have used a wireless communication protocol to unlock a tank access valve. This solution eliminate the need of using locking mechanical devices on the access pipe, outside of the building, which are complex, expensive and unreliable. This technology allows the collection truck driver to unlock the tank access with his portable mobile computer without having to access the building, interacting with the personnel or interrupting the normal operations to complete the tank pumping. This technology, which can also remotely transmit to the driver the amount of grease collected, allows the company to manage inventories precisely and in real time.

Illustration of the product

To discover other projects completed by Oceatec for the food processing industry , follow this link.